As the start of a new school year approached, students and staff at Northwest Middle School in Coralville, Iowa were getting ready to head back. The only problem: the school was undergoing significant upgrades over the summer and the construction on the building wasn’t going to be ready for final inspection before the bell rang in September. So, when the Egan Company team got a call from general contractor, Knutson Construction, it sprang into action and made the 3.5 hour drive to help get the job done.

ANSWERING THE CALL

The middle school renovation project was expected to be completed on time, ahead of the 2024 school year in September. A 58,000 square foot expansion and additional 50,000 square foot remodel of the school’s auditorium, cafeteria, kitchen, and offices was set to accommodate an additional 500 students. When the original contractor did not have sufficient labor, Todd VerNess, Egan’s Southern Minnesota Business Group Manager, received a call on a Tuesday evening from General Contractor and long-time partner, Knutson Construction.

For the rest of the evening, Todd went to work with Jason Tentis, Egan Company Senior Project Manager, to find a solution and provide electricians to help keep the project on schedule. The following morning, Egan sent a crew down to Coralville to supplement the local electrician and ensure the project was completed on time.

Egan’s team of electricians worked diligently, putting in extra hours to make sure everything was completed properly, safely, and on schedule. Thanks to the extra support on short notice, the school doors opened on time, welcoming students and staff for another great year.

As I was walking the jobsite on Wednesday and Thursday – seeing the Egan trucks in the parking lot – I was humbled by the partnership we have with Egan. No matter the situation, your team is always there to help. It was incredible!

Tom Leimer, Senior Vice President at Knutson Construction

Every project Egan is involved in receives the same dedication and commitment to collaboration and excellence. Egan’s people-driven philosophy and relationship-based approach has helped hundreds of projects reach their goals, and has laid a strong foundation for future success and partnerships.

A dream came true for a football fan last April when Jason Lindula, Egan Company Safety Coordinator, was gifted a trip-of-a-lifetime.

A dream came true for a football fan last April when Jason Lindula, Egan Company Safety Coordinator, was gifted a trip-of-a-lifetime.

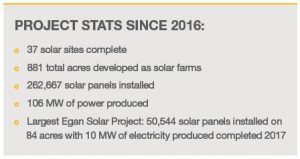

Egan’s solar site projects vary in size, location, time of year, and type of solar panels – fixed-tilt or tracking. “Tracking” solar panels track the sun’s progress across the sky throughout the day, whereas the fixed-tilt solar panels stay in place. Last summer, 150 Egan electricians were on the 65-acre St. Joseph Solar Farm project to install 28,188 fixed-tilt solar panels.

Egan’s solar site projects vary in size, location, time of year, and type of solar panels – fixed-tilt or tracking. “Tracking” solar panels track the sun’s progress across the sky throughout the day, whereas the fixed-tilt solar panels stay in place. Last summer, 150 Egan electricians were on the 65-acre St. Joseph Solar Farm project to install 28,188 fixed-tilt solar panels.

For many active duty military members, transitioning out of the service can be daunting. Finding housing, employment, and acclimating back into the routine of daily life is a huge hurdle to overcome. And, although disciplined and highly-trained, many military members still struggle with unemployment.

For many active duty military members, transitioning out of the service can be daunting. Finding housing, employment, and acclimating back into the routine of daily life is a huge hurdle to overcome. And, although disciplined and highly-trained, many military members still struggle with unemployment. “At times, it is a little confusing for me, but a lot of the habits from the military are still very transferable to my new career,” Martagon said. “I still would do them every day with or without rank.”

“At times, it is a little confusing for me, but a lot of the habits from the military are still very transferable to my new career,” Martagon said. “I still would do them every day with or without rank.”