News

Improve Energy Efficiency in Your Refrigeration Systems

September 16, 2024

The energy used to operate industrial refrigeration systems account for approximately 5.7% of the total industrial energy consumption in the United States according to the U.S. Department of Energy. Industrial facilities require significant energy demands, which can affect the costs of running the facility, as well as impacting the carbon footprint of the company. When it comes to refrigeration systems, maintaining peak performance is critical to ensure the quality and efficiency of the products and goods being held within the facility, and energy efficiency may not be at the top of mind for system operators. However, implementing energy efficiency strategies can reduce operating costs, improve the carbon footprint of the facility, and optimize the way the systems are run.

IDENTIFY INEFFICIENCIES WITH ENERGY AUDITS

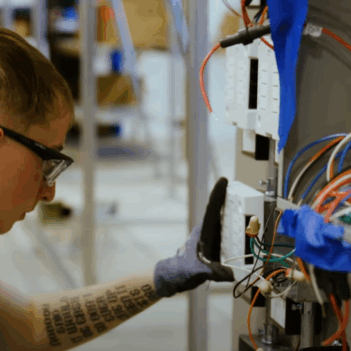

Conducting regular energy audits can help identify areas within your facility that can be upgraded. Analyzing your refrigeration system’s patterns, energy consumption, and overall operational health is the first step to enhancing the way the system is run. Working with Egan’s industrial refrigeration experts and UL 508A Panel Shop ensures that nothing is missed in a system audit, and can help establish plans to improve the energy efficiency within your facility.

UPGRADE TO ENERGY-EFFICIENT EQUIPMENT

Once energy efficiency opportunities have been identified through an energy audit, consider upgrading your equipment to maximize the efficiency within your facility. Newer refrigeration systems are designed to consume less energy while delivering optimal performance, resulting in significant cost savings over time. Energy efficient industrial refrigeration systems are becoming industry standard and operate at the same or better performance than older equipment. With increased performance at reduced operating costs, energy efficient industrial refrigeration systems can make a significant difference in the way facilities are run.

IMPLEMENT SMART CONTROLS AND AUTOMATION

Whether you are updating legacy systems, overhauling your entire refrigeration systems, or are looking for small upgrades to improve efficiency, smart controls and system automation technology can help. Custom refrigeration controls, like Egan’s Refrigeration-IQTM, enable operators to monitor and adjust energy consumption in real-time, improving the energy consumption of the system without compromising performance. Additionally, automation can integrate within your facility to adjust throughout the day. Configuring day/night settings, defrost cycles, and other adjustments can improve the way your system runs. Rather than equipment running at full capacity 24/7, automatically adjusting the settings can optimize the way the whole facility works.

IMPROVE YOUR FACILITY’S REFRIGERATION OPERATIONS

Prioritizing energy efficiency not only benefits the bottom line but also contributes to a more environmentally friendly operation. Facility operators can configure custom settings based on their specific needs and system requirements, so the refrigeration equipment utilizes only the energy necessary to ensure product quality and safety.

Find industrial refrigeration solutions that work for you with Refrigeration-IQTM controls from Egan Company. Our UL 508A Panel Shop in Champlin, Minn. can design and manufacture custom control panels that meet your needs. From system design to project commissioning, our CIRO certified engineers can work with you to improve the energy efficiency within your facility. Get in touch with Egan’s refrigeration experts to learn how to maximize the performance of your industrial refrigeration system.