In an increasingly automated world, the constr uction industry has stayed relatively manual. Machines simply can’t replicate the level of precision and technique required to install building systems; however, Egan Company’s U.L. 508A Panel Shop has found one way to use automation to its advantage.

uction industry has stayed relatively manual. Machines simply can’t replicate the level of precision and technique required to install building systems; however, Egan Company’s U.L. 508A Panel Shop has found one way to use automation to its advantage.

Precision, speed, and safety are the cornerstones of any successful shop. Whether for an in-house job or a customer, the goal is to deliver a product quickly and correctly – the first time. And that’s why our panel shop implemented the Steinhauer ModCenter, an automated modification tool that provides fast, clean cut holes in each control panel.

Shop professionals previously measured, drew, and cut enclosures by hand – taking up to four hours per panel. Although this is a time honored way of providing a quality panel, it is not efficient and leaves room for human error or injury.

By allowing for multiple clean cut outs and back panel drilling/tapping tasks to be completed all at once, the machine improves the overall quality of each control panel.

Egan’s Panel Shop wiremen program the Steinhauer ModCenter to cut each panel per customer specifications. By eliminating the need for wiremen to manually measure, drill, tap, and process, the time for each panel is reduced to about 30 minutes – 87.5% less than if done manually.

This machine frees up a lot of time for our wiremen to work on other aspects of our projects, and get panels out the door much quicker. We estimate it does the work of nearly two people.

-Tim Blair, Egan Panel Shop Manager

Once specifications are programmed, it can be saved as a template for future use – making repeat orders or modification of standard equipment even faster. Delays and waste are greatly reduced, and shop personnel are less likely to be injured during the drilling and milling process.

“This tool enhances Egan’s already excellent safety program, by reducing the risk associated with cutting and drilling into a panel with power tools,” said Jeff Hawthorne, Egan Company Senior Vice President. “We appreciate the efficiency of this machine, but we appreciate the increased safety it provides the shop even more.”

With this great new addition to the panel shop, Egan is now able to be more responsive to customer’s needs and produce more consistent products with a promotion of greater safety.

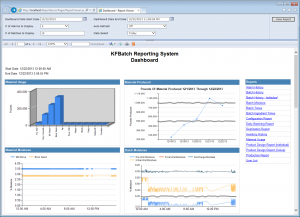

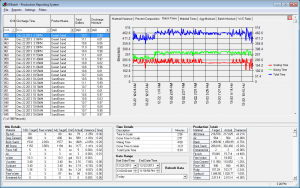

In concrete batching plants, accuracy and quality are the top priority. Comprehensive and informative quality control processes ensures that concrete facilities’ can provide customers with the safest and highest quality product possible. Egan Company’s KFBatch System delivers on this promise with quality control results that tie directly back to batch tickets.

In concrete batching plants, accuracy and quality are the top priority. Comprehensive and informative quality control processes ensures that concrete facilities’ can provide customers with the safest and highest quality product possible. Egan Company’s KFBatch System delivers on this promise with quality control results that tie directly back to batch tickets. This information is available on a customizable dashboard, allowing concrete facilities to reduce product waste, enforce strict quality standards, and quickly tie batches back to any recalled products.

This information is available on a customizable dashboard, allowing concrete facilities to reduce product waste, enforce strict quality standards, and quickly tie batches back to any recalled products.

Whether steam or hot water, boilers require routine tune ups to run at top efficiency and produce low utility costs. A complete boiler tune up from Egan Company’s licensed and trained technicians will measure efficiency, correct any problems, and improve overall performance.

Whether steam or hot water, boilers require routine tune ups to run at top efficiency and produce low utility costs. A complete boiler tune up from Egan Company’s licensed and trained technicians will measure efficiency, correct any problems, and improve overall performance.

Secured, safe, efficient – deliver hassle-free remote connection to concrete batching systems with Egan Company’s newest product, EganConnect.

Secured, safe, efficient – deliver hassle-free remote connection to concrete batching systems with Egan Company’s newest product, EganConnect. Advantages of a Single Electronic Access Control System

Advantages of a Single Electronic Access Control System From roof-top-units to cooling towers to chillers, our trained coil cleaning team can service your system to:

From roof-top-units to cooling towers to chillers, our trained coil cleaning team can service your system to:

uction industry has stayed relatively manual. Machines simply can’t replicate the level of precision and technique required to install building systems; however, Egan Company’s U.L. 508A Panel Shop has found one way to use automation to its advantage.

uction industry has stayed relatively manual. Machines simply can’t replicate the level of precision and technique required to install building systems; however, Egan Company’s U.L. 508A Panel Shop has found one way to use automation to its advantage.