To be successful in the construction industry is no different than being successful in any feat, it requires consistency. Success demands day in and day out preparation, proper tools and effective training, equipment, and conditions. When it comes to safety, this recipe for success is the same.

From our company leaders to our

field leaders and all of our employees in between, we believe the key to being

safe is being proactive and consistently engaging our people with safety in

everything we do. At Egan Company, safety is everyone’s job. It’s everyone’s

job to make sure our safety policies and procedures are being consistently

executed. It’s everyone’s job to help us achieve our goal of ZERO injuries and

to come home to our family and friends at the end of the work day.

Through much hard work and a

refined focus, Egan achieved its Total Recordable Incident Rate goal of <

2.0 for 2018. Our incident rate for the year was 1.87 (down from 2.42 in 2017) which is substantially below the

average rate for specialty trade contractors in Minnesota (4.70). This was

accomplished with over 1.8 million hours worked.

“Moving the safety needle in 2018 was a great achievement for us as a company,” said Reid Romer, Egan Company Safety Director. “Our safety incident rate is a direct reflection of the time and energy we’ve invested collectively to minimize risk and protect our people. This progress comes from specific safety initiatives we committed to improving over the past few years and we are now seeing rewarding results.”

An example of one of the changes

made in 2017 was within the new employee on-boarding process. This process was

specifically addressed after recognizing a pattern that new employees were

consistently getting injured within their first six months on the job. Egan

acknowledged this, invested in changing it, and elevated it on its priority

list. As a result, new employee injuries have significantly decreased.

Though we are proud of this progress

in 2018, Egan has no plans of slowing down its drive to be the best-in-class

when it comes to safety. Utilizing employee and peer group feedback and

experiences from last year, the bar is set even higher for 2019.

“Our goal is to continue to engage

with our employees and do everything we can to keep this injury reduction track

trending in 2019,” said Romer. “We’ll continue to fill the information and

training pipelines, as well as remain diligent with planning in both the

pre-mobilization and throughout our jobs. This, along with a team approach, will

continue to give us an opportunity to lead the way for safety on our projects

this year and in the future.”

A: “We can help hold each other accountable by constantly looking out for each other, pointing out unsafe actions, and unsafe situations in the workplace or on jobsites. By continuing to hold each other to a high standard of safety, we can achieve our safety goals.” — Sean Moore, Control Panel Technician

A: “We can help hold each other accountable by constantly looking out for each other, pointing out unsafe actions, and unsafe situations in the workplace or on jobsites. By continuing to hold each other to a high standard of safety, we can achieve our safety goals.” — Sean Moore, Control Panel Technician A: “Achieving zero injuries allows Egan to be even more competitive in our marketplace. And, overall it would be exciting to reach such a great safety milestone.” — Jon Kroening, Electrical Field Leader

A: “Achieving zero injuries allows Egan to be even more competitive in our marketplace. And, overall it would be exciting to reach such a great safety milestone.” — Jon Kroening, Electrical Field Leader A: “Requiring and enforcing our crews to wear 100% PPE [Personal Protection Equipment] at all times is always first and foremost in maintaining safety. We also follow all OSHA standards, Egan guidelines, and make sure our crew never overextends themselves. We promote using carts, lifts, or whatever is needed to assure the job stays safe.” — Jim Drummond, Plumber Field Leader

A: “Requiring and enforcing our crews to wear 100% PPE [Personal Protection Equipment] at all times is always first and foremost in maintaining safety. We also follow all OSHA standards, Egan guidelines, and make sure our crew never overextends themselves. We promote using carts, lifts, or whatever is needed to assure the job stays safe.” — Jim Drummond, Plumber Field Leader A: “Egan’s safety practices, as well as the General Contractor’s, make it easy for us to solve most safety issues. However, if there is ever a situation where a crew member doesn’t feel comfortable, I remind them to walk away and bring it to my attention. We always stress that each person is most responsible for their own safety.” — Tim McKie, Electrical Field Leader

A: “Egan’s safety practices, as well as the General Contractor’s, make it easy for us to solve most safety issues. However, if there is ever a situation where a crew member doesn’t feel comfortable, I remind them to walk away and bring it to my attention. We always stress that each person is most responsible for their own safety.” — Tim McKie, Electrical Field Leader A: “Each morning we talk through safety challenges, and as a team we come up with the best plan to ensure we all stay safe. Egan’s Safety team has also done specific training on our jobs, and we’ve had equipment companies show us how to properly and safely operate their lift equipment. It’s clear that safety is a part of everything we do.” — Mike Kush, InterClad Field Leader

A: “Each morning we talk through safety challenges, and as a team we come up with the best plan to ensure we all stay safe. Egan’s Safety team has also done specific training on our jobs, and we’ve had equipment companies show us how to properly and safely operate their lift equipment. It’s clear that safety is a part of everything we do.” — Mike Kush, InterClad Field Leader A: “Always be aware of your surroundings and anticipate possible safety challenges before they happen. Working in this industry involves risks to not only ourselves, but also to the public and others around us, so having awareness to recognize these risks is highly important.” — Todd Grandt, ATS Project Manager

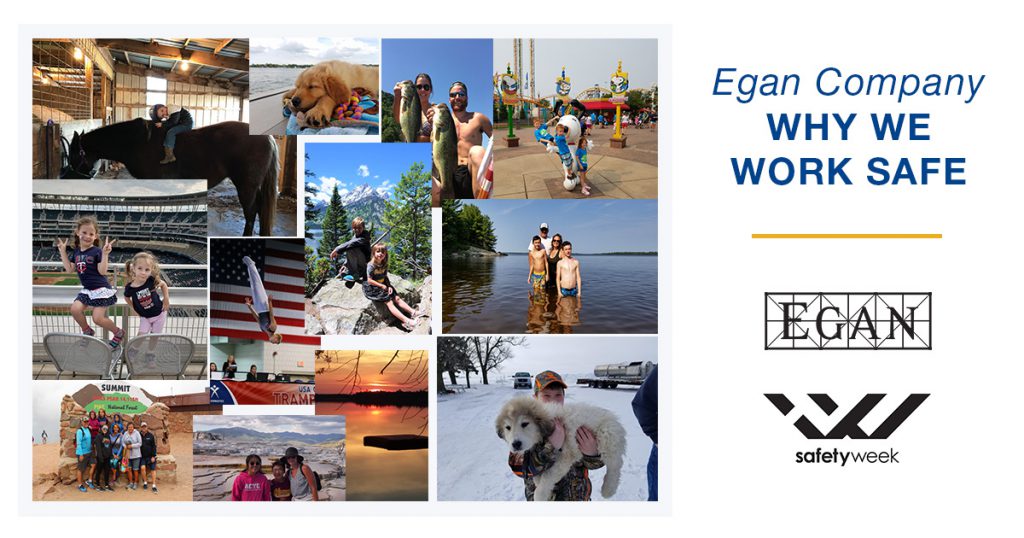

A: “Always be aware of your surroundings and anticipate possible safety challenges before they happen. Working in this industry involves risks to not only ourselves, but also to the public and others around us, so having awareness to recognize these risks is highly important.” — Todd Grandt, ATS Project Manager A culture of safety is an intangible value of Egan Company – every project, every employee, every day. To remain safe every day takes hard work and commitment, so what is it that motivates Egan employees to work safe? Though there are A LOT of reasons, throughout the month of September employees submitted photos for our annual

A culture of safety is an intangible value of Egan Company – every project, every employee, every day. To remain safe every day takes hard work and commitment, so what is it that motivates Egan employees to work safe? Though there are A LOT of reasons, throughout the month of September employees submitted photos for our annual  “Why We Work Safe” contest to tell us why they personally work safe.

“Why We Work Safe” contest to tell us why they personally work safe.