With an abundance of fertile farm land and innovative revolutionaries, Minnesota has been a force to be reckoned with for centuries in the agricultural and manufacturing industries. In the early years, farming was all done by hand, with a little help from heavy and difficult-to-operate machinery. Over the years, new inventions have made farming significantly easier, including the use of hydropower in watermills to increase grain production in Minneapolis (aka the “Mill City”).

With these new innovations, farmers were able to produce and distribute crops at a more rapid pace, creating a need for more automated processes. To fill this need, many of Minnesota’s largest companies began to revolutionize the food industry even further by making production simpler and more automated.

With these new innovations, farmers were able to produce and distribute crops at a more rapid pace, creating a need for more automated processes. To fill this need, many of Minnesota’s largest companies began to revolutionize the food industry even further by making production simpler and more automated.

Industrial and manufacturing facilities began cropping up to help provide food globally. Most of these facilities were primarily in the southern part of the Twin Cities due to the close proximity to existing grain production facilities and river access. As the industry has exponentially grown, Egan Company has steadfastly provided its multi-trade services to grow customer business and enhance production in numerous facilities across the Midwest.

Today, food production follows a standard process –  production on a farm/ranch, processing in a manufacturing facility, distribution to stores/restaurants, and consumption at a home/restaurant. But there’s a lot that goes into the processing step that many people don’t realize. Equipment needs to frequently be moved or upgraded, production lines require routine maintenance, facilities are expanded – and that’s when Egan Company is called.

production on a farm/ranch, processing in a manufacturing facility, distribution to stores/restaurants, and consumption at a home/restaurant. But there’s a lot that goes into the processing step that many people don’t realize. Equipment needs to frequently be moved or upgraded, production lines require routine maintenance, facilities are expanded – and that’s when Egan Company is called.

Recently, Egan Company trades provided TreeHouse Foods upgrades to a private label food processing facility.

In May 2016, a building addition was added onto the existing facility. Egan provided underground plumbing and HVAC for the new space, with piping and sheet metal prefabricated in Egan’s Mechanical Shops. Once construction was complete, two, fully-functioning production lines were assembled for making and distributing snack foods across North America.

The teams worked alongside each other to install each piece of equipment for the production lines. Millwrights rigged, assembled, and precisely aligned the equipment, while process controls electricians followed up with the electrical installation for each piece of equipment.

“Working with other Egan trades is great. From my experience, customers enjoy having multiple trades with Egan on the same jobsite. They see a safe and clean environment with excellent communication.”

-Cole Witteman, Egan Millwright Field Leader

In addition, the control panels for the kitchen and conveyance systems were prefabricated in Egan’s U.L. 508A Panel Shop, then installed onsite to integrate with the existing system. Along these production lines, robot arms were installed by millwrights to pack and move the snack food along through production. These robots are programmed to be compatible with the control panel at each station of the line.

For industries like food production, Egan’s willingness to help other trades succeed and our in-house, multi-trade collaboration is an advantage unmatched by competitors.

Project Team: TreeHouse Foods

Egan Services Provided: Chilled water piping, plumbing, sheet metal exhaust duct, electrical installation, PLC/HMI programming, CAD, robot assembly and installation, cat walks, precise alignment & equipment moving, conveyance, electrical controls, and routine plant maintenance.

With these new innovations, farmers were able to produce and distribute crops at a more rapid pace, creating a need for more automated processes. To fill this need, many of Minnesota’s largest companies began to revolutionize the food industry even further by making production simpler and more automated.

With these new innovations, farmers were able to produce and distribute crops at a more rapid pace, creating a need for more automated processes. To fill this need, many of Minnesota’s largest companies began to revolutionize the food industry even further by making production simpler and more automated. production on a farm/ranch, processing in a manufacturing facility, distribution to stores/restaurants, and consumption at a home/restaurant. But there’s a lot that goes into the processing step that many people don’t realize. Equipment needs to frequently be moved or upgraded, production lines require routine maintenance, facilities are expanded – and that’s when Egan Company is called.

production on a farm/ranch, processing in a manufacturing facility, distribution to stores/restaurants, and consumption at a home/restaurant. But there’s a lot that goes into the processing step that many people don’t realize. Equipment needs to frequently be moved or upgraded, production lines require routine maintenance, facilities are expanded – and that’s when Egan Company is called. Ohio-based UltraFlo. Given its design – clean, simple, and free of cluttered pipes or wires – it was perfect for the highly trafficked, rarely closed bathrooms of the casinos.

Ohio-based UltraFlo. Given its design – clean, simple, and free of cluttered pipes or wires – it was perfect for the highly trafficked, rarely closed bathrooms of the casinos. Another major cost saving perk is its one mixing valve system, which allows maintenance personnel to adjust the faucet temperature for the entire bathroom through a single valve. This differs from battery-operated systems, which each have their own controls, resulting in a very costly and time-consuming process when maintenance is needed.

Another major cost saving perk is its one mixing valve system, which allows maintenance personnel to adjust the faucet temperature for the entire bathroom through a single valve. This differs from battery-operated systems, which each have their own controls, resulting in a very costly and time-consuming process when maintenance is needed. At a local warehouse for an international food distribution company, forklifts had triggered traditional sprinklers in the freezer section by accidentally hitting them when moving products. The cost

At a local warehouse for an international food distribution company, forklifts had triggered traditional sprinklers in the freezer section by accidentally hitting them when moving products. The cost A challenge with the new system was that a traditional heat detector could not be installed due to it being part of the sprinkler head – which a forklift could (once again) hit. To overcome this challenge, Egan installed a specially-engineered cable connected directly to the sprinkler pipe. If that cable reaches a specific temperature, the alarm will set off the sprinklers.

A challenge with the new system was that a traditional heat detector could not be installed due to it being part of the sprinkler head – which a forklift could (once again) hit. To overcome this challenge, Egan installed a specially-engineered cable connected directly to the sprinkler pipe. If that cable reaches a specific temperature, the alarm will set off the sprinklers. The University of Minnesota’s Athletes Village provides the campus a new multi-sports facility for Gopher student athletes. The brand new $166 million sports center will officially open in January 2018, housing facilities for men’s and women’s basketball and the football team.

The University of Minnesota’s Athletes Village provides the campus a new multi-sports facility for Gopher student athletes. The brand new $166 million sports center will officially open in January 2018, housing facilities for men’s and women’s basketball and the football team. construction, Egan Company has been involved with various expansions and developments of this luxury shopping mall.

construction, Egan Company has been involved with various expansions and developments of this luxury shopping mall. As a customer for nearly 10 years, Mound-Westonka Schools rely on Egan Company for a number of maintenance needs, including boiler tune-ups and electrical outages. In summer 2016, Mound-Westonka High School had suddenly lost power, and a member of the school’s facility management team noticed smoke in the building. As Egan regularly works on various schools in the District, Egan’s Service team was called to the site.

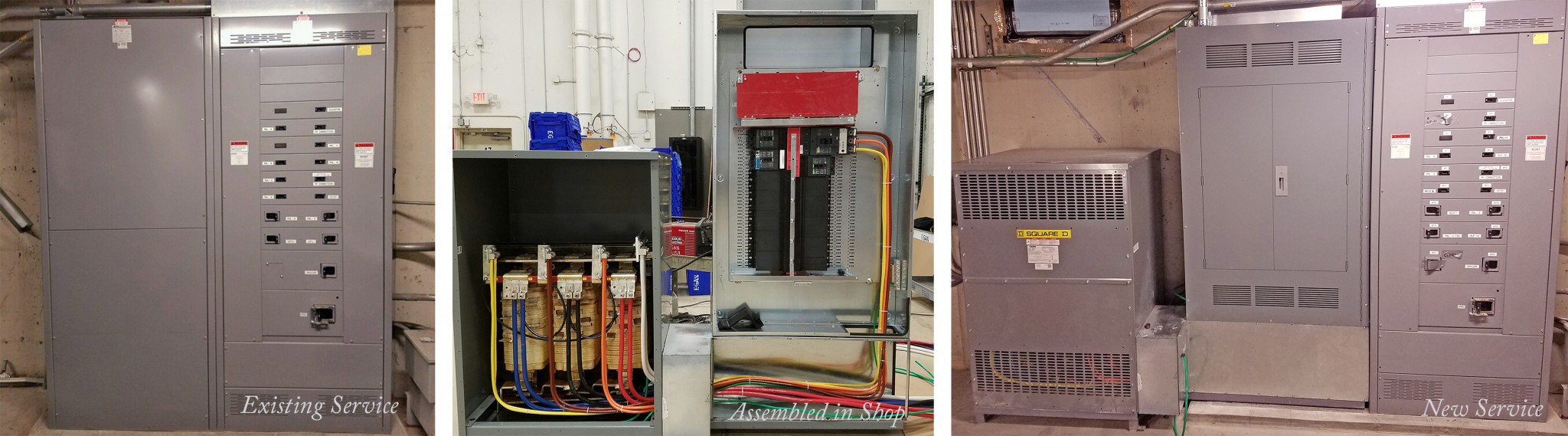

As a customer for nearly 10 years, Mound-Westonka Schools rely on Egan Company for a number of maintenance needs, including boiler tune-ups and electrical outages. In summer 2016, Mound-Westonka High School had suddenly lost power, and a member of the school’s facility management team noticed smoke in the building. As Egan regularly works on various schools in the District, Egan’s Service team was called to the site. arrival of the utility company to disconnect the school from the utility grid so they could safely evaluate the problem.

arrival of the utility company to disconnect the school from the utility grid so they could safely evaluate the problem. supply, fiber optic cabling, and all the wiring in the tunnel had to be repaired. With a new transformer, more than 6,400 feet of cable was installed to reconnect the service entrance conductors to the main electrical switchgear. New fiber optic cabling was installed to regain access to the District server.

supply, fiber optic cabling, and all the wiring in the tunnel had to be repaired. With a new transformer, more than 6,400 feet of cable was installed to reconnect the service entrance conductors to the main electrical switchgear. New fiber optic cabling was installed to regain access to the District server.

The Ramsey County Library system just opened its newest renovated branch in Shoreview, Minn. This new 38,000-square-foot building increases space from the previous location by 10,000 square feet, and gives library-goers a new experience with interactive displays, 3D printers, and additional computers and seating.

The Ramsey County Library system just opened its newest renovated branch in Shoreview, Minn. This new 38,000-square-foot building increases space from the previous location by 10,000 square feet, and gives library-goers a new experience with interactive displays, 3D printers, and additional computers and seating. curtainwall and 300 square feet of aluminum panels on the exterior of the building. Interior glass, sliding glass doors, mirrors, and one all-glass interior wall add to the overall modern-feel of the Library. Sound performance glass was also installed between the children and adult areas for sound control.

curtainwall and 300 square feet of aluminum panels on the exterior of the building. Interior glass, sliding glass doors, mirrors, and one all-glass interior wall add to the overall modern-feel of the Library. Sound performance glass was also installed between the children and adult areas for sound control.